BUILDING VALUES

H.C. Muddox Core Values guide our behavior and our business. The test of a company’s values is not what is written or said, but by the actions and decisions made every day.

|

|

INTEGRITYIntegrity is consistent behavior that is genuine, truthful and forthright. BELIEF BEHAVIORS

|

|

|

SAFETYSafety is an environment in which people take uncompromising responsibility to protect themselves and others. BELIEF BEHAVIORS

|

|

|

RESPECTRespect is recognizing each person, their contribution and perspective. BELIEF BEHAVIORS – Appreciate each person’s role – Communicate in a sincere manner |

|

|

CUSTOMER FOCUSOur customers’ success promotes our success.

BELIEF BEHAVIORS – Be leaders in our markets, products and industry

|

|

|

QUALITYQuality is performance that meets or exceeds expectations and industry standards.

BELIEF BEHAVIORS – Train and communicate

|

|

|

INNOVATIONInnovation is forward thinking that results in creative ideas that position our organization for success.

BELIEF – Necessary to succeed

BEHAVIORS – Encourage and welcome all ideas

|

|

|

FINANCIAL SUCCESSFinancial success is assurance of the profitability and stability of the organization.

BELIEF – Everybody is a stake holder

BEHAVIORS – Measure and recognize a dedicated workforce

|

INTEGRITY

Integrity is consistent behavior that is genuine, truthful and forthright.

BELIEF

– Fairness

– Open and Honest Communication

– Accountability

– Accessibility

BEHAVIORS

– Honoring your commitment

– Take responsibility for your behavior

– Being a good listener / open minded

– Open-door environment

– Address difficult situations in a timely manner

– Base decisions on understanding of all available facts and circumstances

SAFETY

Safety is an environment in which people take uncompromising responsibility to protect themselves and others.

BELIEF

– Zero accidents is attainable

– We are responsible for each others well being

– Safety promotes good morale and employee commitment

– Resources must be committed to safety

– Housekeeping is critically important

BEHAVIORS

– Communicating the importance of safety is a top priority

– Teach people how to work safely

– Lead by example

– Open-door environment

– Each person has the responsibility to take action to correct unsafe behavior or condition

– Everyone participates in improving our safety programs

– Recognize and reward good safety behavior

RESPECT

Respect is recognizing each person, their contribution and perspective.

BELIEF

– Respect is the foundation of our relationships

– Each individual’s actions influence ongoing respect

– Respect is reciprocal

BEHAVIORS

– Appreciate each person’s role – Communicate in a sincere manner

– Listen to people with an open mind

– Have a genuine interest in people’s success

– Recognize accomplishments

– Respect our work environment and company assets

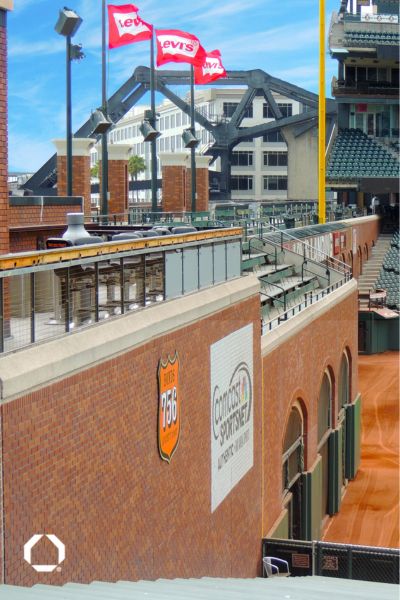

CUSTOMER FOCUS

Our customers’ success promotes our success.

BELIEF

– Every employee plays a role in our customers’ success

– Each customer has unique needs

– Build long-term relationships

BEHAVIORS

– Be leaders in our markets, products and industry

– Never take our customers for granted

– Understand and respond to customer needs

– Provide solutions to solve customer issues

– Meet our commitments

– Express appreciation for their business

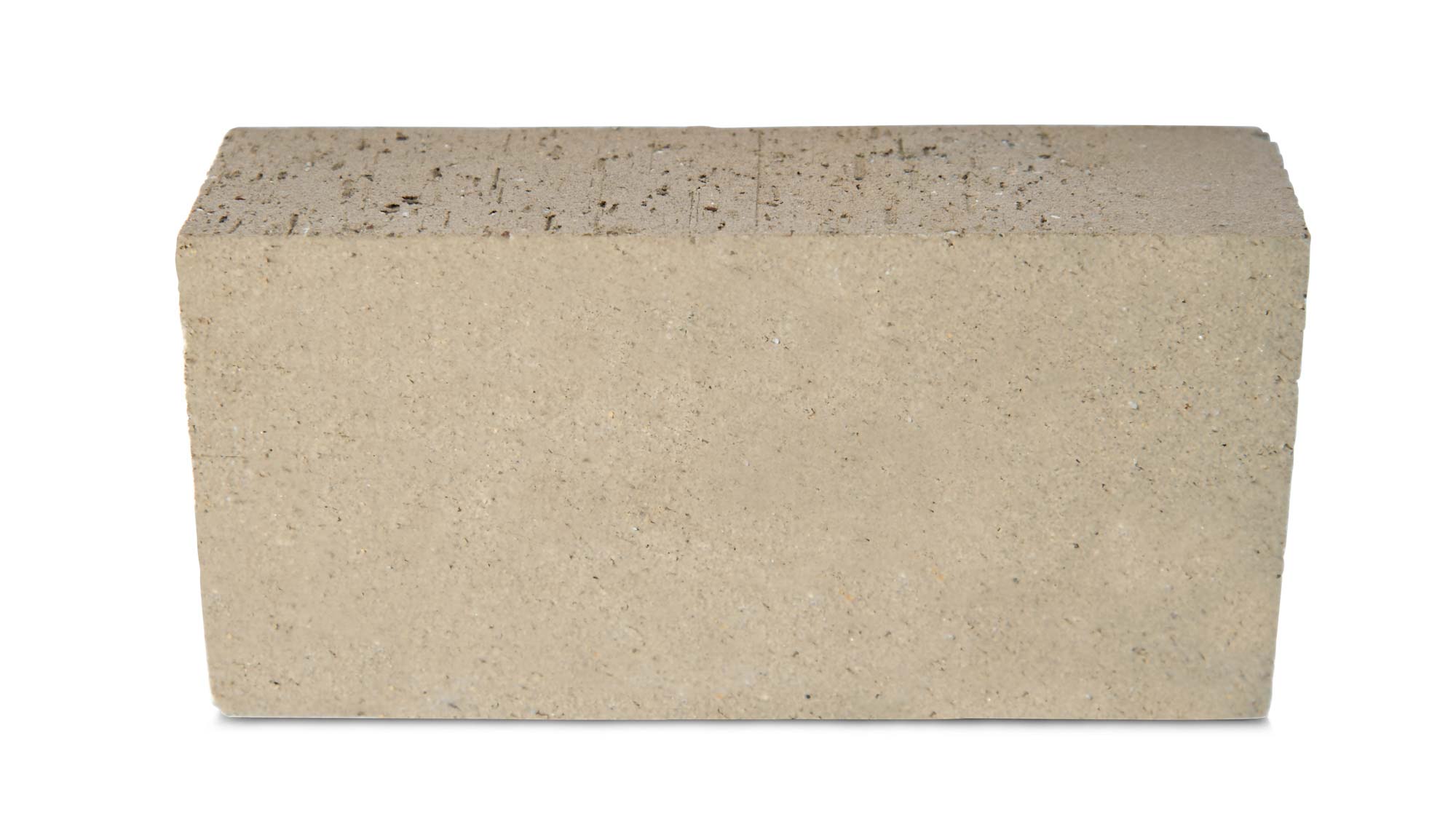

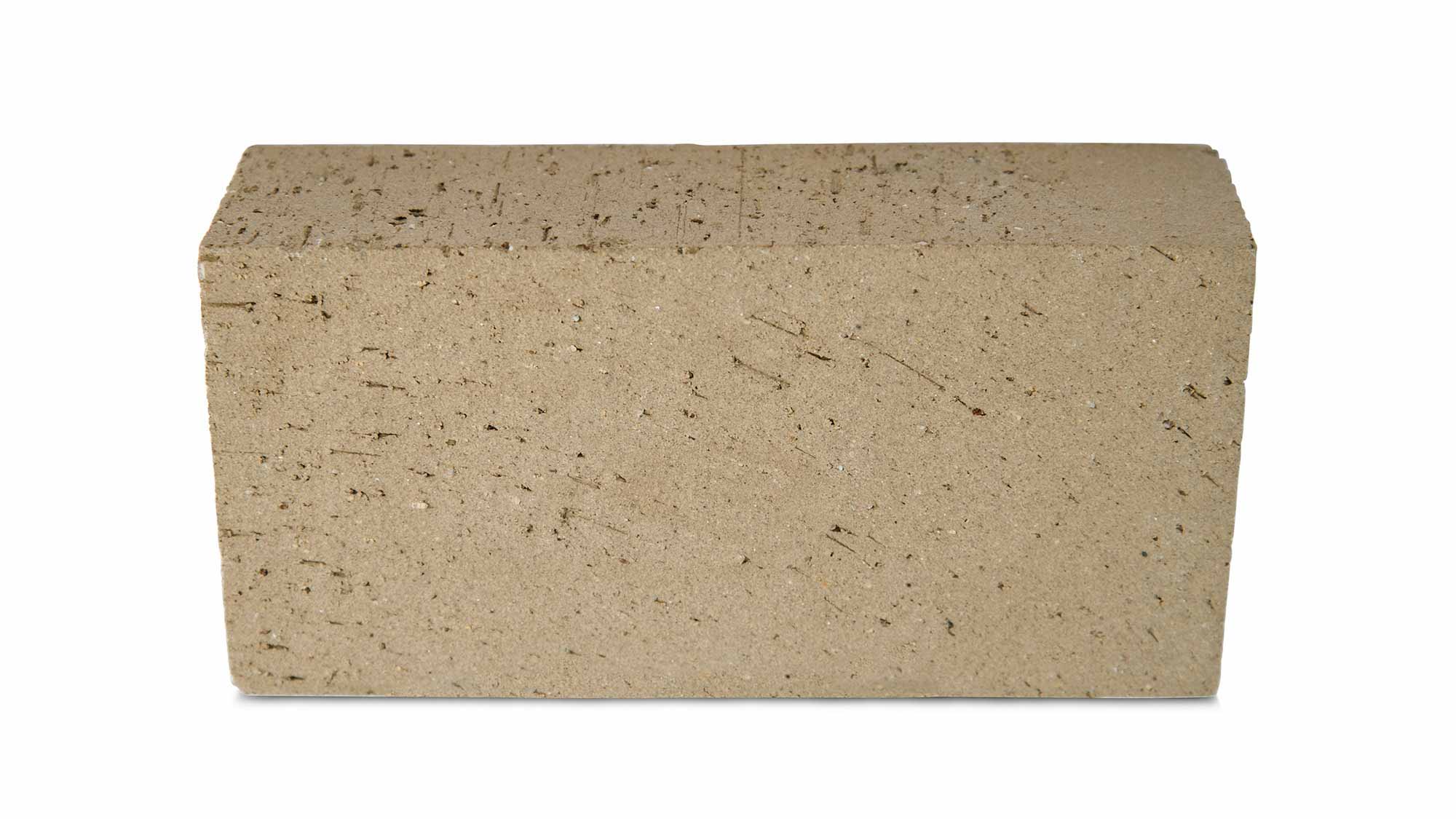

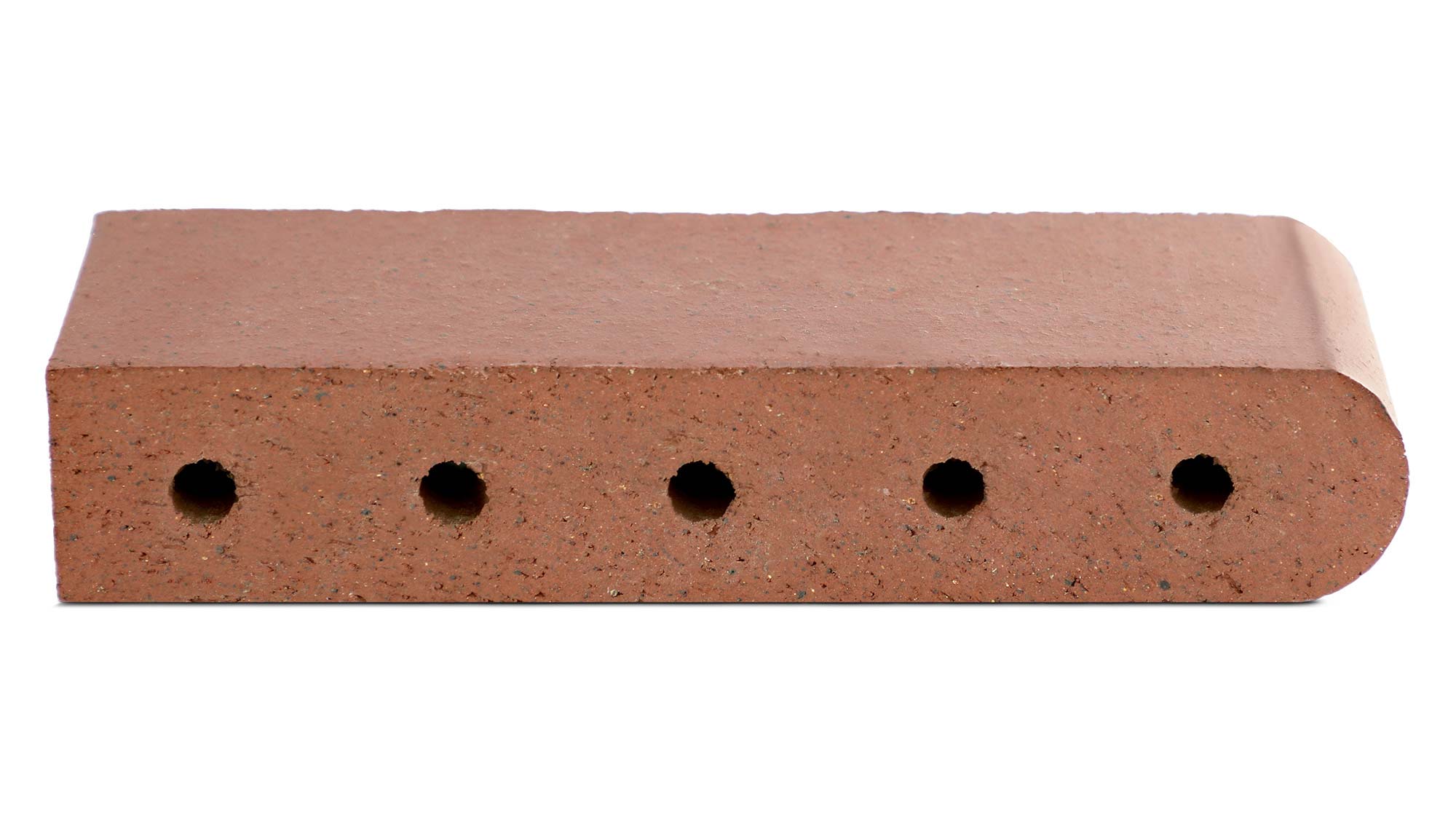

QUALITY

Quality is performance that meets or exceeds expectations and industry standards.

BELIEF

– Applies to all aspects of our business

– Enhance our value to our customers and our people

– Differentiates us from competitors

– Contributes to long-term success

– Attracts quality people

BAHAVIORS

– Train and communicate

– Measure to ensure that standards are met

– Identify and address the cause of the issue

– Be responsive to feedback

– Direct resources to support quality

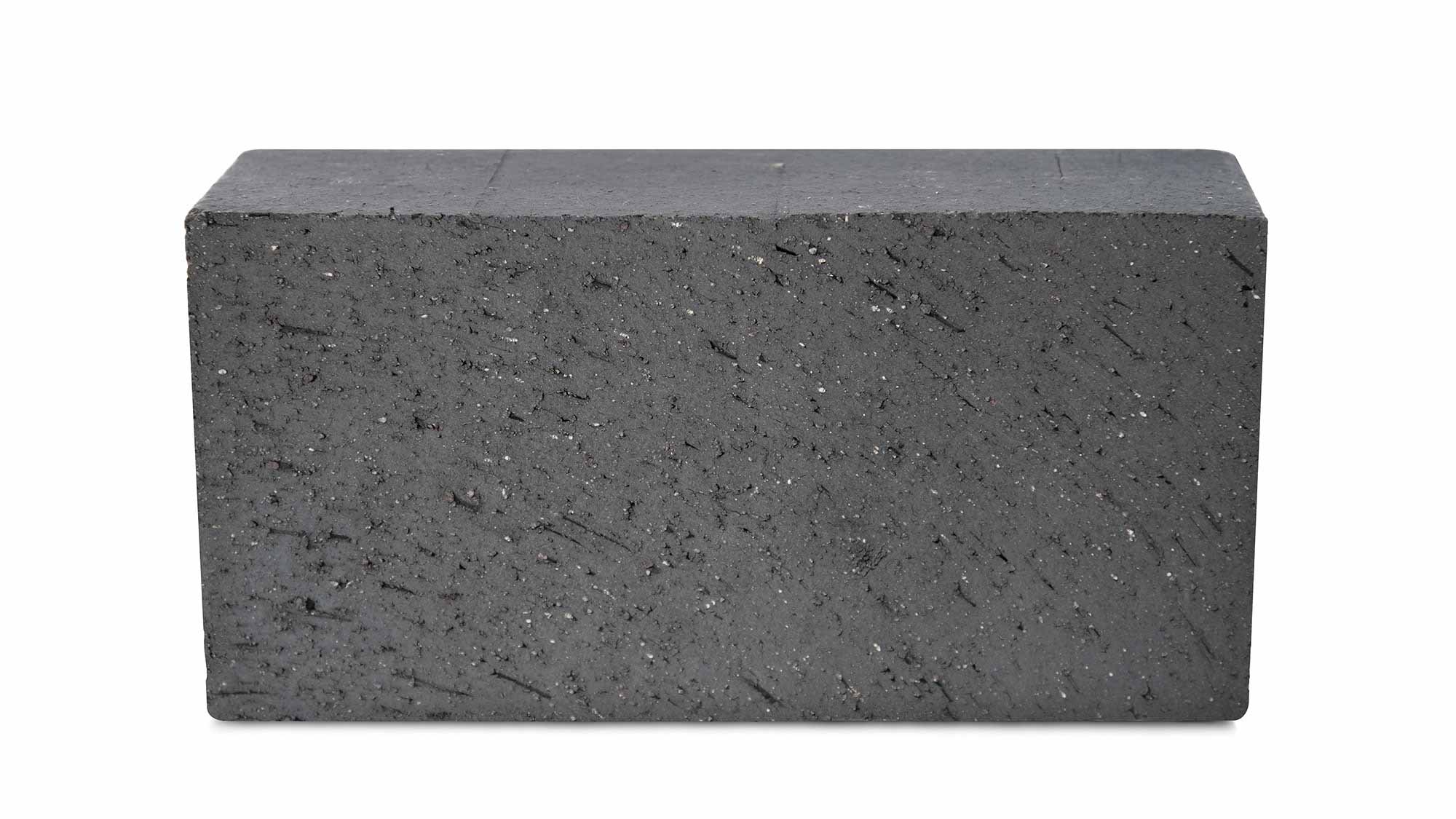

INNOVATION

Innovation is forward thinking that results in creative ideas that position our organization for success.

BELIEF

– Necessary to succeed

– Everyone is capable of a creative idea

– Risk is inherent in creativity

– Balance free-thinking with practicality

– Requires investment of resources

BEHAVIORS

– Encourage and welcome all ideas

– Objective analysis prior to investment

– Provide feedback on all ideas

– Recognize and reward successful innovation

FINANCIAL SUCCESS

Financial success is assurance of the profitability and stability of the organization.

BELIEF

– Everybody is a stake holder

– Everyone influences financial success

– Everyone benefits from financial success

– Provides opportunities for our people

– Enables growth

– Attracts and retains quality people and partnerships

– Benefits our communities

BEHAVIORS

– Measure and recognize a dedicated workforce

– Communicate business conditions

– Maximize efficiencies without compromising safety and quality

– Reinvest in the company

– Support community organizations and activities